Pipe Type: Stainless Steel Welded Pipe

Application: In Chemical Industry, Coal, Oil Field Open Machine, Building Materials Heat-resistant Parts

Specification:Outside Diameter: 15.9mm-3000mm

Wall Thickness: 2mm-60mm

Standard: ASME, EN, GB, ASTM, DIN, JIS, API, GOST

Steel Grades:304, 304/L, 304H, 310/S, 310H, 316, 316L, 321, 321H

Surface: Annealed, Pickling, Polished

Packing: Waterproof Paper Wrapped, Packed in Wooden Cabins

Email:sales@sqsteelpipe.com

Whats App: 008613761124029

Skype:steelproducts

Wechat:137463635

Stainless Steel Welded Pipe

Duplex Welded Stainless Steel Pipe is in the application of Petrochemical and Chemical industry, Onshore and Offshore Oil & Gas field of exploration, production and processing, Pulp and Paper-making industry, Ship Buliding industry, Coal industry and etc. Also used in producing all kinds of conventional weapons, the barrel, artillery shells and so on.

Common Applications for Stainless Steel Tubing Stainless steel tubing has a number of uses in a wide variety of industries. It can be used during manufacturing in processing plants or can become part of a final product. Stainless steel tubing can also be used in pipelines to transport oil, gas, water, or chemicals.

The general features of our DSSP: superior corrision resistance, such as pitting corrosion, crevice corrosion, abrasion corrosion; better weldability and mechanical properties; excellent intergranular corrosion resistance and better cost- effectiveness.

Stainless steel can withstand corrosive or chemical environments due to its smooth surface.

Inspection & Quality Control:

Chemical Composition Analyzing Flattening

Metallographic Test Flare & Flange

Mechanical Properties Test Reverse Bend

Hydraulic Test Reverse Flattening

Non-destructive Test, including X-Ray Flaw Detection Tensile Strength

Dimensional Checking Hardness

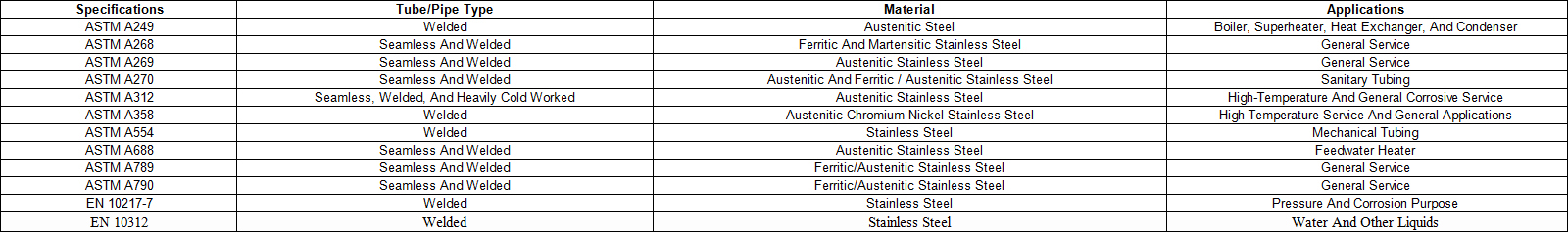

Welded Tube Standard Specifications

Welding Methods

Welded stainless steel tube is made from long strip or sheet, passed a rolling machine, then the strip edges is welded longitudinally and melt together, using various welding processes, making welding beam is as same as base metal, and form into tube shape.

The sheet width is desired tube outside diameter, the width should be calculated before manufacturing.

TIG

Tungsten Inert Gas welding, another name for Gas tungsten arc welding (GTAW), is an arc welding process that uses a non-consumable tungsten electrode to produce the weld. The weld area and electrode is protected from oxidation or other atmospheric contamination by an inert shielding gas.

EFW

Electric Fusion Welding, Electric Fusion Welding (EFW steel pipe) refers to an electron beam welding, the use of high-speed movement of the electron beam directed impact kinetic energy is converted to heat the workpiece so that the workpiece leaving the melt, the formation of the weld. It is mainly used for welding dissimilar steel welding sheet or which high power density, metal weldment can rapidly heated to high temperatures, which can melt any refractory metals and alloys.

ERW

Electric Resistance Welding, high-frequency electrical current is passed between the material edges, then the edges are forced together under pressure as a butt joint and then welded by heating the material to high temperatures.

DSAW

Double Submerged arc welded, similar to other pipe manufacturing processes, the manufacture of Double Submerged Arc Welded Pipe involves first forming steel plates into cylindrical shapes. The edges of the rolled plate are formed so that V-shaped grooves are formed on the interior and exterior surfaces at the location of the seam. The pipe seam is then welded by a single pass of an arc welder on the interior and exterior surfaces.

LSAW

Longitudinal Submerge-arc Welded, LSAW (Longitudinally Submerged Arc Welded Steel pipes) in leaflets plate as raw material, the steel plate in the mold or molding machine pressure (volume) into using double-sided submerged arc welding and flaring from production.

HFW

High Frequency Welding, HFW welded steel pipes are widely preferred in Oil, Natural Gas, Water and other liquids transportation and distribution lines, heating, cooling, ventilation piping and steel structures for construction and other general purposes by means of precise production tolerances and high capacity manufacturing method.

Heat treatment is generally required after manufacture, this process improves stainless steel welded tube properties, help welded tube suitable for wide applications

Welded Tubes Quality Control

All stages from raw material to finished products, tube manufactured under strict quality control, making sure tube having stable mechanical properties, excellent surface finish and high dimensional accuracy.

Standard Testing Optional Testing

Tensile Strength test Ultrasonic test

Flattening test Hydrostatic test

Flare test Air Under Water test

Flange test Grain Size

Dimensional inspection Corrosion test

PMI Metallographic

Hardness test Radiographic test.

Eddy Current test