Pipe Type:SSAW Pipe,Spirally Submerged Arc Welding Pipe

Application: Used for oil/gas/water Transmission,Engineering/Offshore/Onshore projects..etc

Specification: Outer diameter:219mm-3500mm

Wall thickness: 5mm-26mm

LENGTH:5.8/6/11.8/12/18/32meters

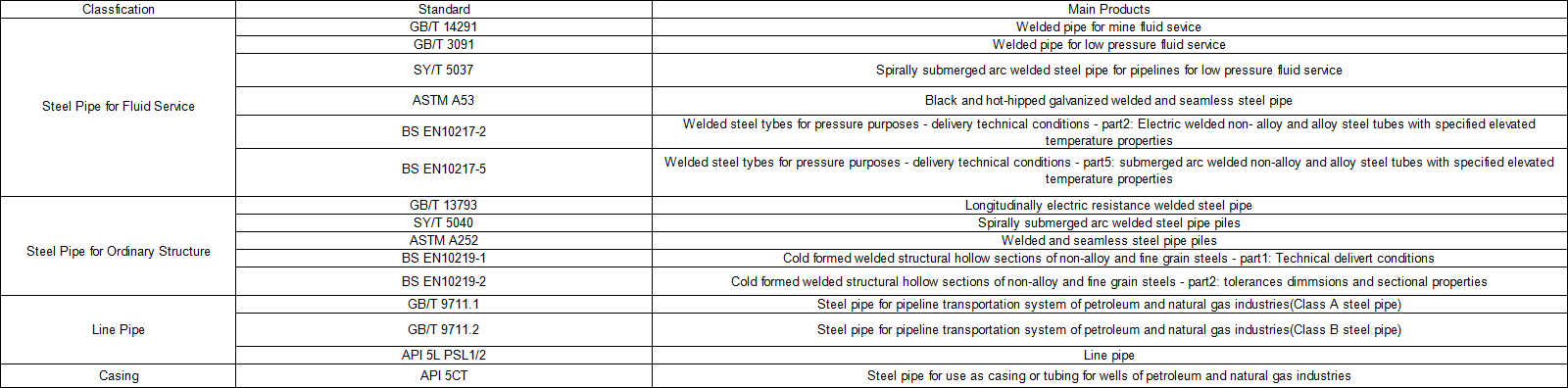

Standard & Grade:ASTM A53: Gr.A, Gr.B;API 5L:Gr.A,Gr.B,X42,X46, X52,X56,X60,X65 PSL1 and PSL2; ASTM A252

End: Square Ends/Plain Ends (straight cut, saw cut, torch cut),Beveled/Threaded Ends

Surface: Black Painting/Oil Painting/Anti-Rust oil/Anti-Corrosive Coating

Packing: Bundled,Plastic Caps Plugged,Waterproof Paper/Bag Wrapped

Email:sales@sqsteelpipe.com

Whats App: 008613761124029

Skype:steelproducts

Wechat:137463635

SSAW pipe

Spiral submerged arc welding(SSAW) is its forward direction and forming tube centerline hose reel molding angle (adjustable), side molding edge welding and weld them into a spiral.

Spiral Submerged-arc Welded Quality Assurance

Spiral welded pipe production by submerged arc method is based on using tandem welding technique for joining inside and outside coil edges, which have been trimmed and beveled by carbide milling for high quality weld structure.

Listing some notes You must know

Oiled marking: Steel after passing wrer oiled to prevent corrosion,and according to user requirements for making.

Leveling Milling: The flat steel anvil machine so that the origal curl,and then thouth the edge milling machine for two-sided steel milling,so as to meet the requirements of the plate width,plate edge parallelism and groove shape.

Shear molding: The steel plate production line along the outer edge of the spiral curl into a tube.

Butt cut: Double-sided submerged arc welding using advanced technology to pre-welding,internal welding,outside wilding.The welded steel pipe using a plasma-foot cut to specification length.

Note:

Welding of hot rolled steel coils takes spiral form after passing through preforming and forming rolls. Excellent exterior weld quality at high production speeds is provided by double submerged arc welding process. Manufactured pipes are cut to the desired lengths at the exit of the pipe machine. Pipe ends are beveled by means of carbide machining for accurate on-site welding.

After the pipe is conveyed to hydrostatic testing and off-line ultrasonic testing and/or real time X-ray inspection, the pipe will be subject to final inspection for the compliance to customer requirements.

Widely preferred longer lengths up to 18,5 m. considerably decreases the cost of pipeline construction resulting in less number of girth welds compared to shorter pipe lengths.

Spiral welded steel pipes are widely used in Oil, Natural Gas, Water and other flammable & nonflammable liquid conveyance and distribution pipelines, steel structures for construction and other general purposes by means of their wide size range.

The SSAW pipe is widely used in long distance pipeline project for transmission of oil, natural gas, water as well as coal gas, and also is used in all kinds of engineering, such as chemical industry, electric power, irrigation, construction and piling etc.

Advantages of ssaw steel pipe

(1) The use of steel strips of the same width enables the production of steel pipes of different diameters, in particular the production of large-diameter steel pipes with narrow strip steel.

(2) Under the same pressure conditions, the spiral welds are subjected to a smaller stress than the straight seams, which is 75% to 90% of the straight seam welded pipes, and can therefore withstand greater pressures. Compared with the straight welded pipe with the same outer diameter, under the same pressure, the wall thickness can be reduced by 10% to 25%.

(3) Accurate size, general diameter tolerance is not more than 0.12%, deflection is less than 1/2000, ellipticity is less than 1%, and sizing and straightening processes are generally omitted.

(4) It can be continuously produced. In theory, it can produce infinitely long steel pipes, and the loss of cutting and cutting tails is small, which can increase the metal utilization rate by 6% to 8%.

(5) Compared with the straight seam welded pipe, its operation is flexible and the adjustment of the replacement type is convenient.

(6) The equipment is light and the initial investment is small. It can be made into a trailer-type flow unit and the welded pipe can be produced directly at the construction site where the pipeline is laid.

(7) It is easy to realize mechanization and automation.

How to increase the stability of the ssaw steel pipe?

1.Small and medium-sized steel, wire rods, steel bars, medium-diameter steel pipes, steel wires and wire ropes, etc., can be stored in a well-ventilated shed, but must be lining up and down.

2.Some small steel materials, thin steel plates, steel strips, silicon steel plates, small-caliber or thin-walled steel pipes, various cold-rolled and cold-drawn steel products, and expensive, easily corroded metal products may be stored in storage.

3.The place or warehouse where spiral steel pipe products are to be kept should be located in a clean and unobstructed place, away from factories and mines that produce harmful gases or dust. Weeds and all debris should be removed from the site to keep the steel clean.

4.Large-sized steel, steel rails, insult steel, large diameter steel pipes, forgings, etc. can be stacked in the open air.

5.In the warehouse must not be stacked together with acid, alkali, salt, cement and other materials that are aggressive to steel. Different types of steel should be stacked separately to prevent confusion and prevent contact corrosion.