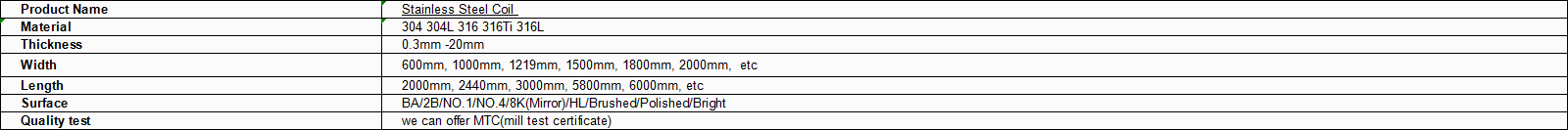

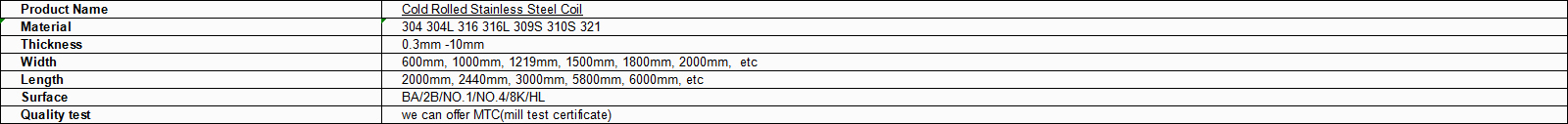

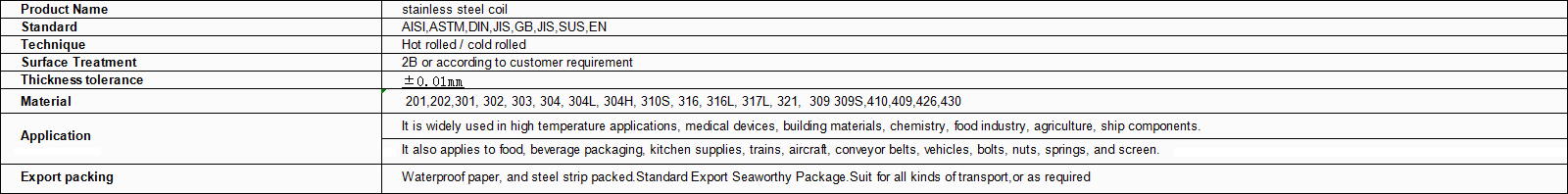

Pipe Type: Stainless Steel Strip Coil, 304 Stainless Steel Coil, 316L Stainless Steel Coil

Application: It is widely used in high temperature applications, medical devices, building materials, chemistry, food industry, agriculture, ship components. It also applies to food, beverage packaging, kitchen supplies, trains, aircraft, conveyor belts, vehicles, bolts, nuts, springs, and screen.

Specification: Cold Rolled Thickness: 0.3mm - 3.0mm

Hot Rolled Thickness: 3.0mm - 80.0mm

Standard: JIS, ASTM, AS, EN, GB

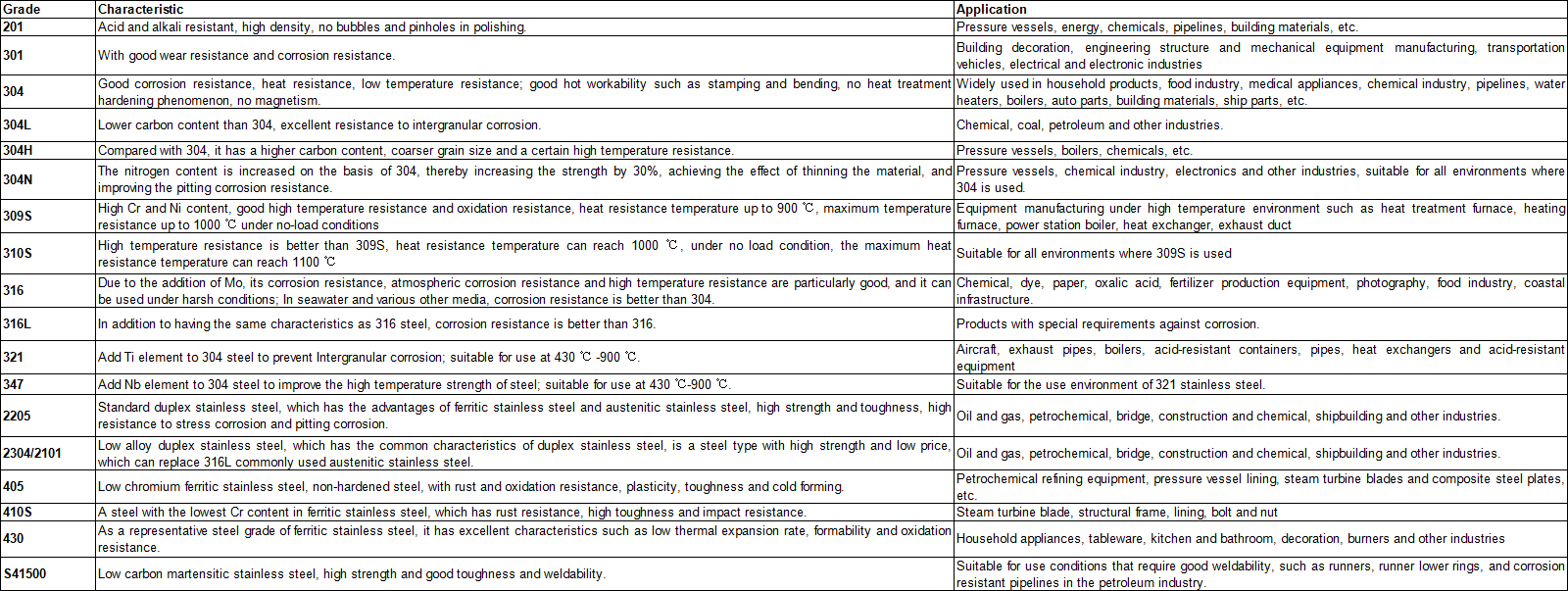

Steel Grades: 201, 202, 301, 304, 321, 309, 310s, 2205, 409, 410, 420, 430, 439, 443, 444, etc

Surface Treatment: Brushed, Mirrored, Sandblasted, Embossed, Titanium-plated, etc

Surface: NO.1, NO.2D, NO.2B, BA, NO.3, NO.4, NO.240, NO.320, NO.400, HL, NO.7, NO.8, etc

Packing: Waterproof paper, and steel strip packed. Standard Export Seaworthy Package

Email:sales@sqsteelpipe.com

Whats App: 008613761124029

Skype:steelproducts

Wechat:137463635

Product introduction

Stainless steel plate is an alloy steel with smooth surface, high weldability, corrosion resistance, polishability, heat resistance, corrosion resistance and other characteristics. It is widely used in various industries and is an important material in modern industry. Stainless steel is divided into austenitic stainless steel, ferritic stainless steel, martensitic stainless steel, and duplex stainless steel according to the structure state.

THE DIFFERENCE BETWEEN 304 AND 316 STAINLESS STEEL

When selecting a stainless steel that must endure corrosive environments, austenitic stainless steels are typically used. Possessing excellent mechanical properties, the high amounts of nickel and chromium in austenitic stainless steels also provide outstanding corrosion resistance. Additionally, many austenitic stainless steels are weldable and formable. Two of the more commonly used grades of austenitic stainless steel are grades 304 and 316. To help you determine which grade is right for your project, this blog will examine the difference between 304 and 316 stainless steel.

304 Stainless Steel

Grade 304 stainless steel is generally regarded as the most common austenitic stainless steel. It contains high nickel content that is typically between 8 and 10.5 percent by weight and a high amount of chromium at approximately 18 to 20 percent by weight. Other major alloying elements include manganese, silicon, and carbon. The remainder of the chemical composition is primarily iron.

The high amounts of chromium and nickel give 304 stainless steel excellent corrosion resistance. Common applications of 304 stainless steel include: Appliances such as refrigerators and dishwashers Commercial food processing equipment Fasteners Piping Heat exchangers Structures in environments that would corrode standard carbon steel.

316 Stainless Steel

Similar to 304, Grade 316 stainless steel has high amounts of chromium and nickel. 316 also contains silicon, manganese, and carbon, with the majority of the composition being iron. A major difference between 304 and 316 stainless steel is the chemical composition, with 316 containing a significant amount of molybdenum; typically 2 to 3 percent by weight vs only trace amounts found in 304. The higher molybdenum content results in grade 316 possessing increased corrosion resistance. 316 stainless steel is often considered one of the most suitable choices when selecting an austenitic stainless steel for marine applications. Other common applications of 316 stainless steel include: Chemical processing and storage equipment. Refinery equipment Medical devices Marine environments, especially those with chlorides present

Grade and Application