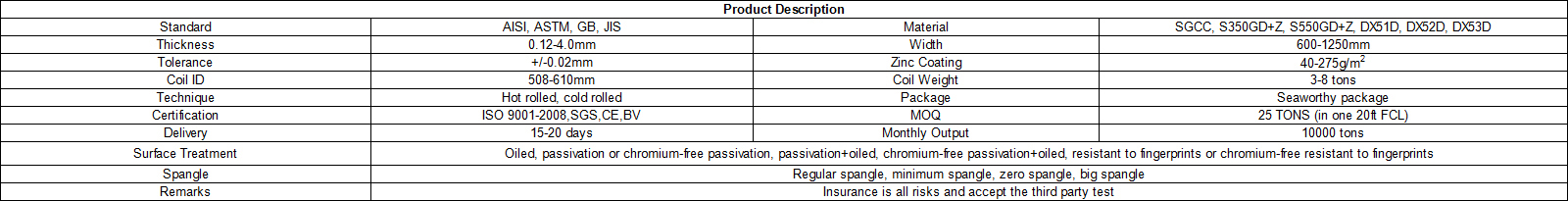

Product Type:Galvanized Steel Coils/ Sheets/ Strips.

Product Standard:EN, DIN, JIS, ASTM

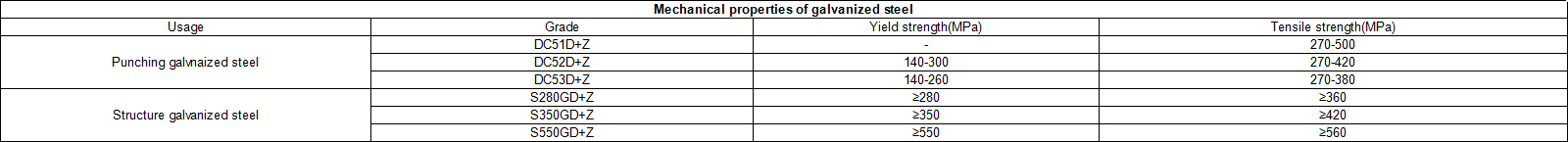

Product Material:DC51D, DC52D, DC54D, DC53D, S250GD, S300GD, S350GD, S450GD, S550GD,etc.

Product Thickness:0.12mm - 6.0mm.

Product Description: Zinc Coating: 40-275g/m2.

Spangle: Normal (non-skinpassed) spangle, Skinpassed spangle, Regular spangle, Minimized spangle

Surface Treatment: Chromate passivated, Non-chromate passivated, Chromate passivated + oiling, Non-chromate passivated+oiling, Anti-fingerprint, Non-chromate anti-fingerprint treatment, Oiling, No treatment

Email:sales@sqsteelpipe.com

Whats App: 008613761124029

Skype:steelproducts

Wechat:137463635

Product Introduction

Galvalume steel is also called Aluminum-Zinc Alloy Coated Steel, Zincalume steel, aluminized zinc steel (aluzinc steel), SGLC, The galvalume metal is composed of 55% aluminium, 43.4% zinc and 1.6% silicon solidified at 600 ~C. Its whole structure consists of aluminium-iron-silicon-zinc, forming a compact quaternary crystal alloy. The surface of the galvalume steel sheet is characterized by smooth, flat and gorgeous stars, and its base color is silver white. The special coating structure makes it have excellent corrosion resistance. The normal service life of galvalume steel sheet is up to 25a, and its heat resistance is good. It can be used in high temperature environment at 315 C. The adhesion between coating and paint film is good, and it has good processing performance. It can be punched, sheared and welded. The surface conductivity is very good.

Product Description of Galvalume Steel Strip

Characteristics of Galvalume Steel

1.Machinability

It can satisfy the processing requirements of rolling, coiling and others processes alike.

2.Thermal resistance

Common HDG steel plate normally works under 230℃, and has its color changed at 250℃, however, Galvalume steel plate cansustain the environment at 315℃ for long time.

3.High reflectivity

Reflection ability of heat and light is twice as much as those ofhot-dip zinc steel sheet, and its reflectivity is more than 0.70, exceeding 0.65 (required by the EPA Energy Star Standard), which is an ideal construction materials of saving energy.

4.Resistance to corrosion

Al-Zn coated steel sheet has better performance in corrosion resistance than GI sheet of the same thickness and its service life is 2-6 times longer than general GI sheet.

Application

1.Appliances Industry

Outer clad sheets for washing machine, refrigerator, television, air conditioner and ventilation system, explosion-proof strip, solar water heater and appliance parts.

2.Industrial Instruments

Electric control cabinet, industrial refrigeration equipment, automatic vending machine.

3.Architecture

Roofs and outside walls of civilian and industrial buildings, garage doors, fencings and window blinds.

4.Agriculture

Piggery, chicken coop, granary, greenhouse pipes, etc.

5.Other

Muffler, heat shields of exhaust pipe and catalytic converter, auto parts & accessories under the frame, signboard in highway.

Precautions While Using

1.The Galvalume steel should be kept away from the alkaline medium.

2.The roof made out of the Galvalume steel requires a slope to help drainage and to alleviate corrosion.

3.The Galvalume steel sheet should have no direct contact with foundation concrete, wet wood, steel, lead and graphite.

4.Use trimmed plate rather than the plate to be cut plate at job site.

5.While the steel plate is piled and processed, its finger-print proof film should be protected from getting black due to dampness and high temperature.

6.If the Galvalume steel is used for foaming and bonding application, then, small-lot test is needed for the initial use, in order to prevent the poor bonding.

7.If the Galvalume steel need to be cleaned,we do not suggest to be cleaned with ethanol. If must to be used, small-lot is needed for the initial use, in order to prevent the damage of the coating.

Quality and Commitment

1.The powdering degree of the product will not exceed 6 grades in 10 years, according to ASTM regulations.

2.No visible cracks after processing and forming within 5 years.

3.No corrosion perforation in 15 years.

Special Note

Normal processing and use conditions are as follows:

1.Normal climatic conditions (extreme cold, extreme heat, high salinity, except strong acid environment).

2.Zinc coating thickness ≥150g / m2.

3.Avoid contact with special chemicals.